- Description

-

Details

Product information

Model

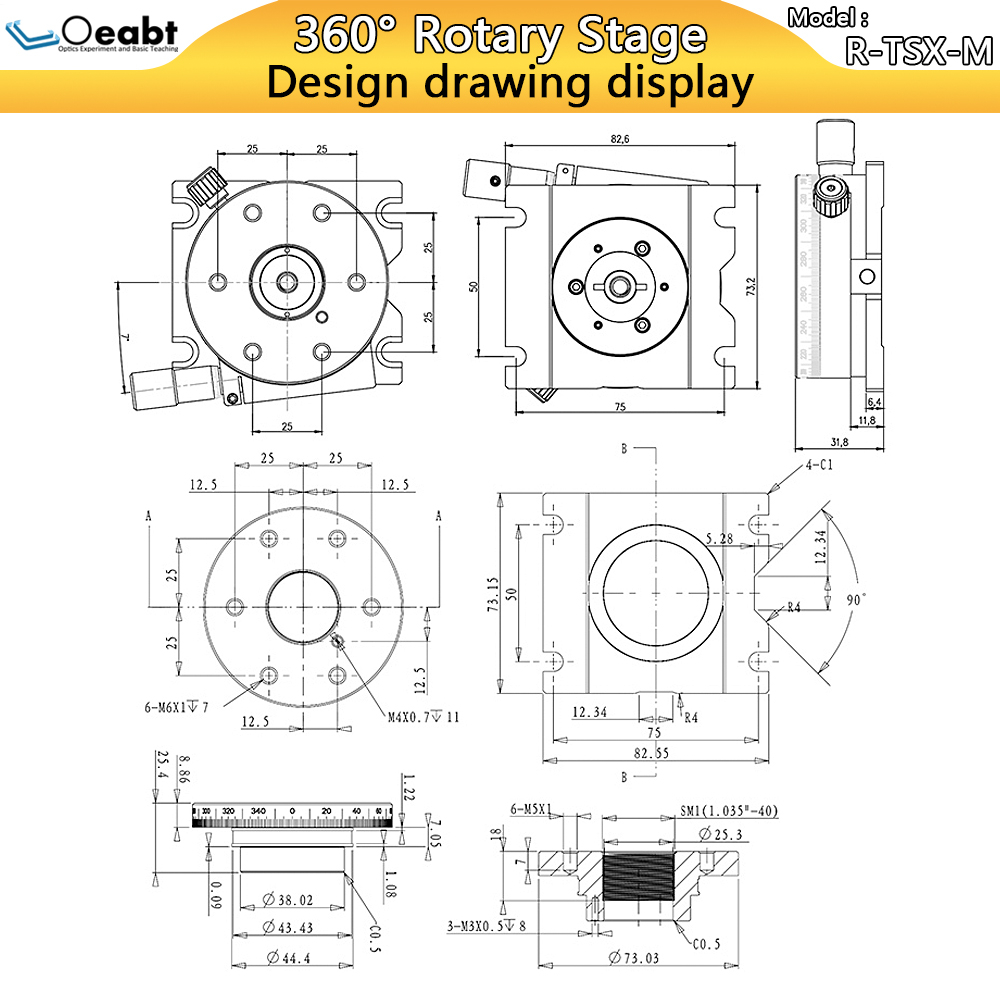

R-TSX-M

Countertop specifications

73mm in diameter

Coarse adjustment stroke

360°, scale 1°

Center hole

SM1(1.035"-40)

Fine adjustment

±5°

Material

#7075 Aluminum alloy

Thread type

M4/M6

Net weight

367g

Load capacity

Coarse adjustment is 25 pounds (11.4kg), fine adjustment is 3.75 pounds (1.7kg)

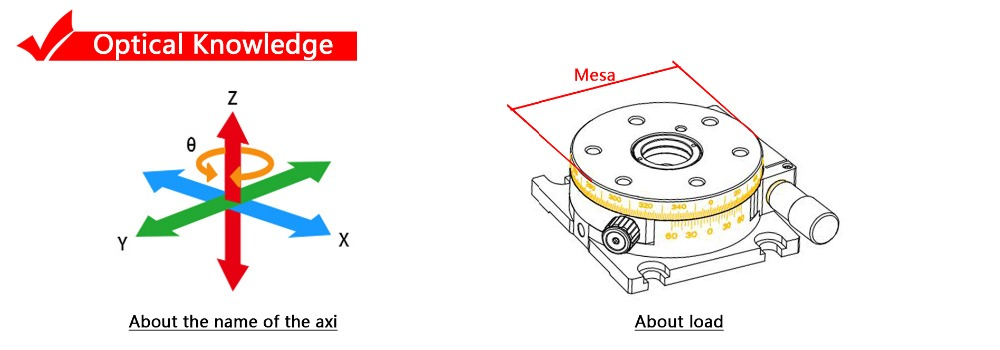

Optical knowledge

About the name of the axis

The horizontal direction is the X axis, the Y axis, and the vertical direction is the Z axis, and the θ axis (θZ) is rotated around the Z axis;

About load

Recommended carrying volume: no more than 1.5 times the table top.

Refers to the force that the platform can bear when the work center of gravity is located in the center of the platform. If it is overloaded, it may make the platform move smoothly. The center of gravity of the objects carried on the surface of the water platform should not exceed the table surface. In order to ensure the movement accuracy and life of the platform, please check the allowable load of the platform when the platform is in use, and do not overload it.

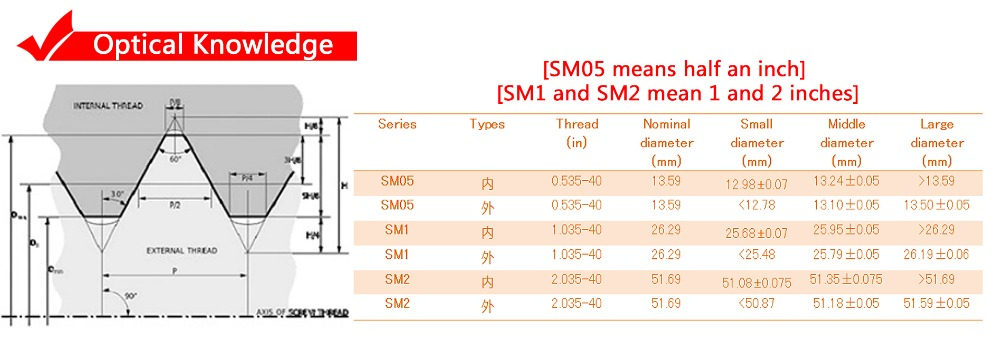

Optical commonly used thread size standard

This is the unique thread of Thorlabs in the United States, not the commonly used optical thread. SM is the code for the thread of the sewing machine in terms of thread expression, but this company in the United States uses it to connect the internal and external threads of the optical lens and the sleeve. The nature of the thread is UNS, and the United States has a special thread with a tolerance accuracy of 2A / 2B. The special place of this thread is 40 teeth per inch regardless of the diameter. The specific dimensions are as follows:

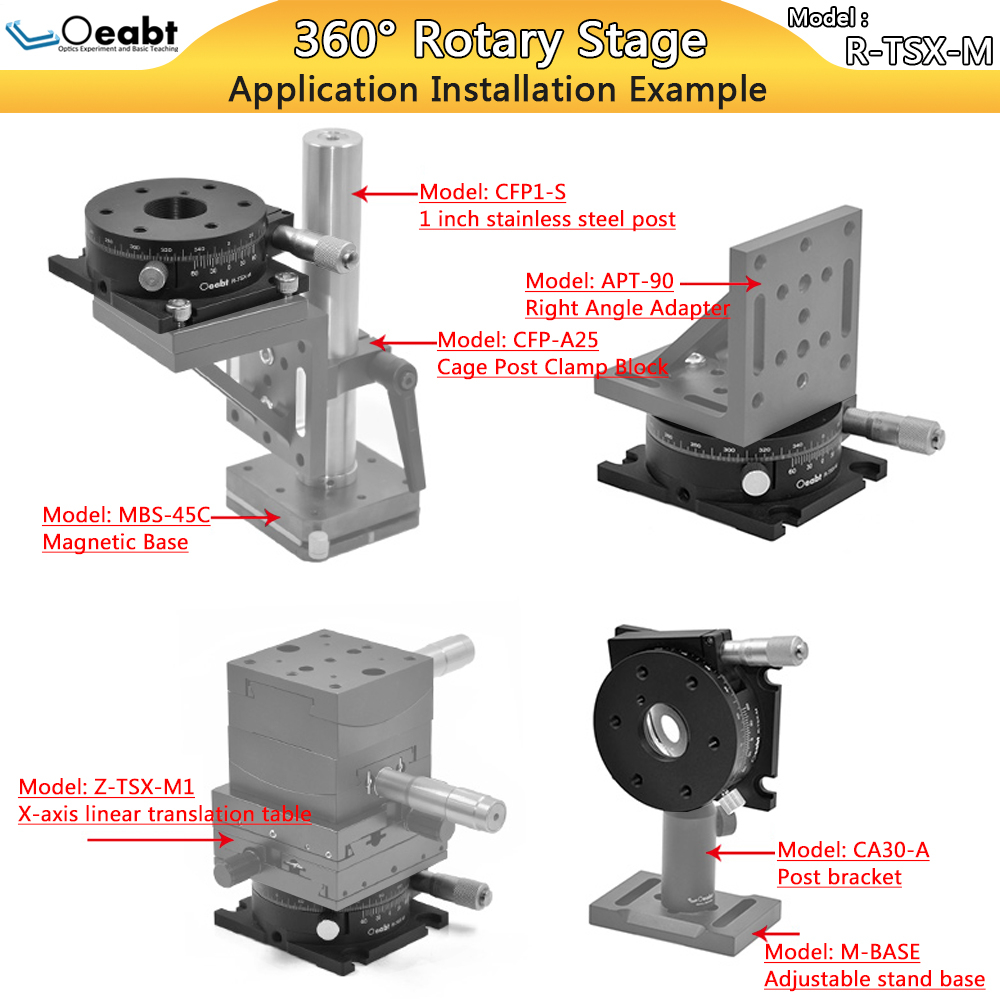

The R-TSX-M rotary mount is a heavy-duty stage that is used to finely adjust optical components, standard optomechanical components, and 30mm cage segments.

Characteristic

▶The rotary table has a rough rotation of 360°, and the graduation of the laser engraving on the rotating disk is 1°.

▶Micrometer and vernier scale can realize fine adjustment of ±5°. Vernier scale is 5 arc minutes with standard accuracy;

▶The M4 screw holes on the table can be installed with the pressure arm models PRK1-65 and PRK2-65;

▶The mounting hole of the center lens is SM1 screw hole (1.035"-40), with a CSK3 snap ring attached;

▶SM1 threaded central hole can be installed with Ø1 inch (Ø25.4 mm), maximum thickness (15mm) optical components;

▶Load capacity: coarse adjustment is 25 pounds (11.4 kg), fine adjustment is 3.75 pounds (1.7 kg);

1 inch stainless steel post

When the locking thumb screw is in the unlocked state, it can be located on the lower side of the stage, and the graduation mark with a division of 1° is the standard, and the 360° all-round smooth and continuous manual rotation adjustment of the stage. When the thumb screw is locked, the micrometer can provide fine adjustment of ±5º. The vernier scale on the lower side is standard, with an accuracy of 5 arc minutes.

The micrometer can provide fine adjustment of ±5º, with the vernier scale on the lower side as the standard, with an accuracy of 5 arc minutes.

The table is regularly distributed with six M6 threaded holes and one M4 threaded hole, and the middle is SM1 ((1.035"-40) threaded hole.

Comes with a CSK3 standard SM1 snap ring, if you need more snap rings, please purchase separately.

There are 4 M6 countersunk head mounting grooves on the bottom surface, which can be fixed on the optical platform. And 2 M6 tapped holes on the side for installation applications on a vertical plane;

The rotary table with the pressure arm is installed. The pressure arm has 2 specifications (6*65mm/8*65mm), if you need to buy, you can take another picture;

Measurement error: Please allow a small measurement error.

- Additional Information

-

Additional Information

Brand Laserlands SKU R-TSX-M - Reviews

-