- Description

-

Details

Product information

Numbering

Parameter Name

Data

01

Body Model

MX2

02

Laser Model

MX2-L360

03

Dedicated Height Gauge

MX2-HR

04

Body Scale Range

0-200mm

05

Laser Scale Range

0-40mm

06

Combined measuring Scale Range

0-240mm

07

Dedicated Height Ruler Range

0-240mm

08

Laser Wavelength

Red Light/Green Light Optional

09

Laser Power

20mW±2%

10

Optical Path Height Visual Resolution

±1mm

11

Horizontal Parallelism Calibration Resolution

±0.6°

12

Vertical Parallelism Calibration Resolution

±0.6°

13

Optical Path Coaxiality Calibration Resolution

X, Y, Z

axis are all≤1%14

Optical Element Installation Pitch Angle Calibration

Resolution±0.6°

15

Optical Component Installation Yaw Angle Calibration

Resolution±0.6°

16

A Fixed Way

Magnetic base / Thumb screw dual mode

17

Material

7075 aluminum magnesium alloy (hard anodized surface)

18

Surface Hardness

≥HV420

19

Datum Accuracy

±25μm

20

Thermal Expansion Coefficient

(20-100℃)um/m.k

21

Combination Quality

853.2g

22

Battery

DC3.7V1200mAh

*The above measurement data is based on r=50cm

flatness ±0.02mm vibration isolation plane test results (non-vacuum)

Characteristic

The MX2 laser aligner is a tool and instrument that can greatly improve the efficiency of optical path construction. It utilizes the characteristics of high brightness, low divergence, and high collimation of the laser. It uses the 180° divergent laser light as the reference guideline to achieve a variety of Auxiliary measurement and optical path calibration functions. Its structure and function are original.

1.Features of laser aligner

►The laser aligner can greatly improve the efficiency of optical path construction, and calibrate the parallelism, perpendicularity and optical path coaxiality;

►The laser has high brightness, small divergence and high collimation;

► 360° divergent laser light can realize a variety of auxiliary measurement and optical path calibration functions;

►Magnetic adsorption design keeps zero combination gap;

►With a special height gauge, it can accurately measure the focal height of any opto-mechanical

component;2.Laser characteristics

►The laser is made of imported laser diodes and constant power circuit boards, with high brightness, clear light, low dispersion and high collimation;

► 360° divergent laser light can realize a variety of auxiliary measurement and optical path

calibration functions;►Magnetic adsorption design keeps zero combination gap;

►With a special height gauge, it can accurately measure the focal height of any opto-mechanical

component;►The shell is made of aviation aluminum-plated insulating paint, which can fully dissipate heat, and

is also shock-proof, anti-drop, anti-static, high-temperature and corrosion-resistant;3.Characteristics of magnetic beam collimator

►Used for beam collimation and height measurement;

►Metric laser scale, total scale length 240mm, 1.0mm graduation;

►Measure the beam height on a magnetic optical platform or breadboard

►Two magnets at the bottom provide holding force for quick placement and removal;

►There is a mounting groove at the bottom for M6 fastening screws;

Description

This instrument has a simple structure and rich functions. It can be used to assist in judging the height of the optical axis of the experimental optical path, and supports the optical path of free space,

track systems and cage systems. For example, calibrate the installation verticality and plane coordinate position of a single optical-mechanical component; calibrate the mutual parallelism, verticality and optical path coaxiality of multiple optical-mechanical component keys; calibrate the installation pitch angle and yaw angle deviation of optical components.Using this instrument to build the optical path does not need to be carried out in a fixed order, even in a compact space, it can be added or removed at any time, and the optical and mechanical components can be moved, and it will not cause the deviation of the optical axis height and the optical path coaxiality. It supports the correction of optical paths built on two or more vibration isolation platforms to the same optical axis height and maintains a high optical path coaxiality.

The laser can be adjusted in the V-shaped grooves on both sides of the body to project horizontal and vertical reference rays respectively. The laser beam is accurately calibrated to ensure that the

perpendicularity and parallelism deviation between the beam and the measurement plane is≤6°, and the zero combination gap is maintained by magnetic adsorption.Both the instrument body and the laser are equipped with a precise scale, and the measurement data such as the height of the optical axis can be read, recorded and reproduced. The instrument adopts two fixing methods: magnetic base and hand screw, which is extremely easy to install and use. , The base is designed with magnetic adsorption, which can be directly adsorbed on the magnetic platform. If it is on a non-magnetic platform, you can use the M6 thumb screw of the base to fix it on the platform. The collimator also supports magnetic adsorption and M6 screw fixing.

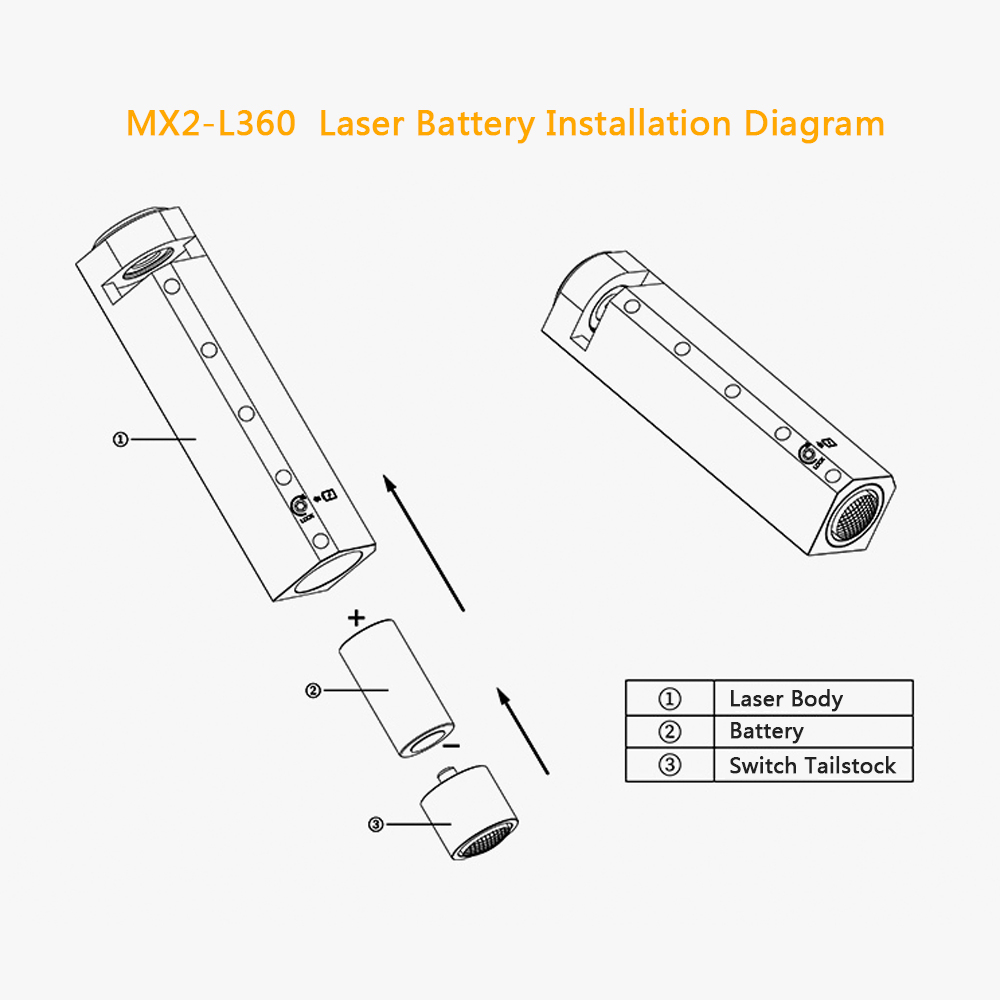

The battery installation steps of the laser device:

use the attached hexagon wrench to screw the screw at the position indicated by the battery indicator icon, and then the switch tailstock can be removed. Insert the battery into the laser in the positive and negative directions as shown in the figure below, push the tailstock and tighten the screws.

Battery Installation Diagram

Measurement error: Please allow a small measurement error.

- Additional Information

-

Additional Information

SKU MX2 - Reviews

-